Aluminum Castings Using Permanent Mold: Accurate Parts for Industrial Purposes

Aluminum permanent mold castings play a vital role in the manufacturing of precision components for numerous industries. These castings use reusable molds, producing exceptional accuracy and surface quality. As the demand for high-performance parts rises, understanding the complexities of this manufacturing process becomes essential. The advantages and applications of aluminum permanent mold castings warrant further exploration, revealing their significance in modern industrial practices.

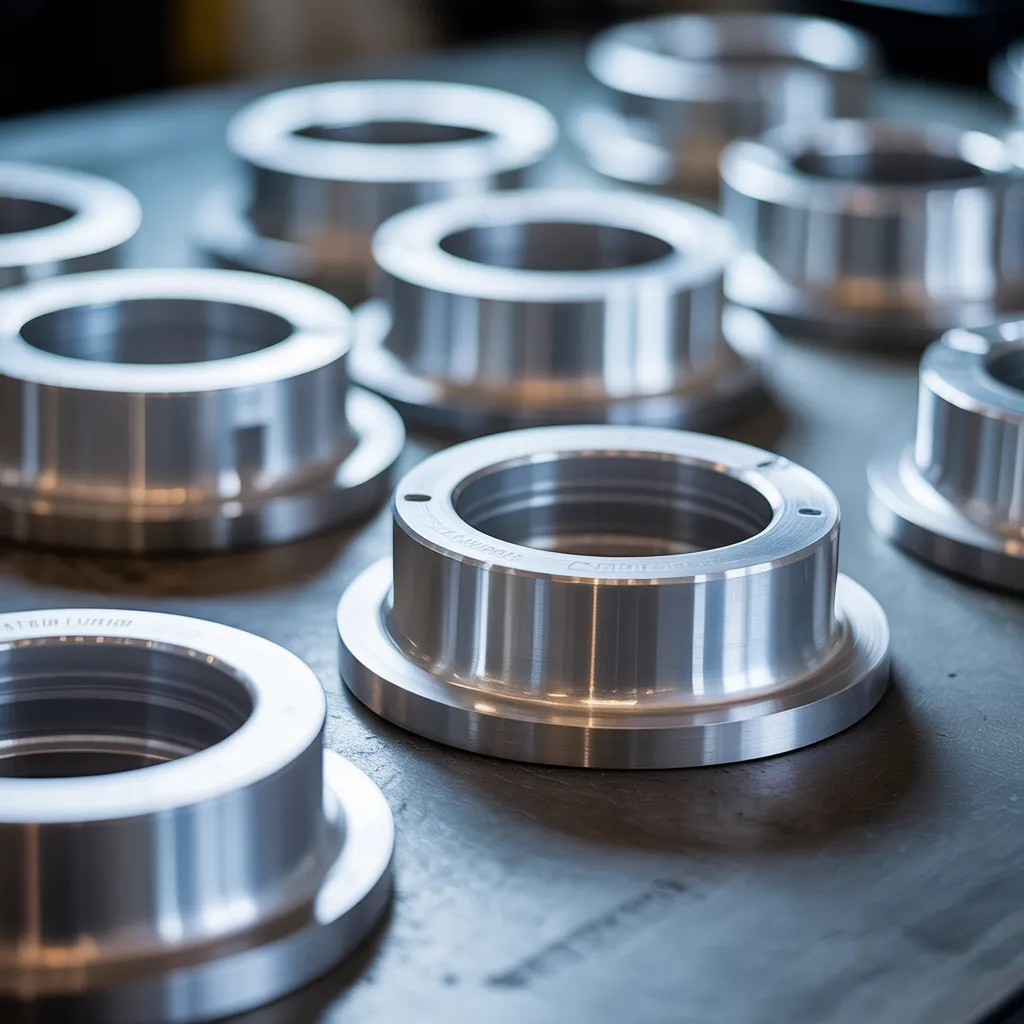

What You Need to Know About Aluminum Permanent Mold Casting

Although multiple casting processes exist, aluminum permanent mold casting stands out for its potential to produce high-quality components with outstanding dimensional accuracy. This technique uses reusable molds, generally constructed from metal, which increases thermal conductivity and allows for rapid cooling of the molten aluminum. As a result, the process delivers intricate geometries and superior surface finishes when compared with sand casting or other processes.

Permanent mold casting with aluminum is especially beneficial for manufacturing pieces that require consistency and durability. The capability to manufacture components with exacting specifications makes it well-suited for industries including automotive, aerospace, and machinery. The process also reduces waste, as the reusable molds can be used repeatedly, making it an environmentally friendly option.

The Manufacturing Process of Aluminum Permanent Molds

Creating aluminum permanent molds requires a exact and systematic process that provides long-term performance and accuracy. First, a master pattern is fabricated, often using materials for example wood or plastic, which serves as the base for the mold design. This pattern is then coated with a release agent to enable easy removal of the final mold.

Next, two halves of the mold are fabricated from high-strength aluminum, guaranteeing tight tolerances and superior surface finish. When the halves are ready, they are assembled, and any essential cooling channels are integrated to control temperature during the casting process.

The mold is then subjected to heat treatment to boost its mechanical properties, increasing its lifespan. Finally, the finished molds undergo comprehensive quality control inspections to verify their compliance with industry standards. This meticulous approach ensures that aluminum permanent molds can withstand the demands of repeated casting cycles while maintaining accurate dimensions and surface quality.

Key Advantages of Aluminum Permanent Mold Castings

Aluminum permanent mold castings deliver multiple important advantages that increase their desirability in manufacturing applications. Significant benefits feature better dimensional accuracy and an outstanding surface finish, which enhance the complete quality of the finished product. Furthermore, the economical manufacturing process renders these castings a sensible option for numerous applications.

Advanced Dimensioning Accuracy

Accuracy in manufacturing processes is vital, and aluminum permanent mold castings stand out for their enhanced dimensional accuracy. This capability results from the rigid molds employed in the casting process, which maintain consistent dimensions throughout production. Aluminum's thermal conductivity also serves a critical function, permitting rapid heat transfer that limits dimensional changes during solidification. Therefore, parts produced through this method experience minimal shrinkage and warping, producing tighter tolerances. Additionally, the repeatability of the permanent molds assures that each casting matches precisely the specified measurements, further increasing accuracy. This level of precision is especially advantageous for industries needing exact specifications, contributing to improved performance and reduced rework in manufacturing processes. Thus, aluminum permanent mold castings stand out for their dimensional integrity.

Superior Surface Finish Finish

Visual attractiveness and practical utility merge in the superior surface finish of aluminum permanent mold castings. This finish results from the refined surfaces created during the casting process, which reduces post-processing requirements. The excellent surface quality enhances the visual aspect of components, making them appropriate for applications where appearance is critical. Additionally, a superior surface finish boosts the performance characteristics of the cast parts, as it lowers friction and wear during operation. The uniformity of the finish also contributes to better adhesion for coatings and paints, delivering longevity and durability. Overall, the excellent surface finish not only increases the aesthetic quality of aluminum permanent mold castings but also enhances their operational efficiency in numerous industrial applications.

Economical Manufacturing Method

Manufacturers find significant advantages in the cost-effective production process of aluminum permanent mold castings. Material waste is reduced via reusable molds in this method, which leads to decreased overall production expenditures. Moreover, the rapid cooling of aluminum in permanent molds allows for shorter cycle times, increasing output efficiency. Mold durability further adds to cost reductions, since they endure multiple casting operations without deterioration. Consistent quality and lower defect rates benefit manufacturers by reducing rework and scrap levels. Furthermore, the capability to create intricate geometries without significant machining operations increases cost effectiveness. Overall, aluminum permanent mold castings present an economical solution for producing high-quality components in various industrial applications.

Comparing Aluminum Permanent Mold Castings against Traditional Approaches

Aluminum permanent mold castings offer distinct advantages over traditional casting methods, specifically in terms of production speed and surface finish quality. This efficient permanent mold approach permits accelerated completion times, making it ideal for high-volume production. Furthermore, surface finishes obtained from aluminum permanent mold castings frequently exceed those produced by traditional methods.

Speed Of Production

While traditional casting methods frequently entail extended processes and substantial setup times, aluminum permanent mold castings significantly enhance production speed. The use of permanent molds allows for rapid cycle times, as they can tolerate high temperatures and quick cooling rates, facilitating faster solidification of aluminum. This efficiency decreases the overall lead time for producing components, making it possible for manufacturers to meet tight deadlines and increase output. Moreover, the reusability of permanent molds reduces the need for frequent mold creation, further streamlining the production process. Therefore, companies can respond more rapidly to market demands, maintaining a competitive edge in industries requiring high-volume production of precision parts. All in all, the speed of production with aluminum permanent mold castings is a significant advantage.

Quality Surface Finishing

When assessing surface finish quality, aluminum permanent mold castings typically outperform traditional casting methods because of their inherent design and production characteristics. The application of durable molds facilitates smoother surface finishes, decreasing the need for extensive post-processing. This generates fewer casting defects, such as porosity and surface irregularities, which are more frequent in sand castings. Additionally, the rapid cooling rates related to permanent molds contribute to finer grain structures, enhancing the overall surface texture. Therefore, parts produced through this method exhibit superior dimensional accuracy and aesthetic appeal. Industries that prioritize surface quality, such as automotive and aerospace, continually favor aluminum permanent mold castings for their ability to meet stringent specifications without diminishing production efficiency.

What Are the Applications of Aluminum Permanent Mold Castings?

Where can one find aluminum permanent mold castings in everyday applications? These components are extensively used in different industrial fields owing to their strength, precision, and outstanding surface finish. Common applications include automotive components such as engine blocks, transmission cases, and structural parts, where durability and low weight properties are essential. Also, they are implemented in the aerospace sector for components for example brackets and housings, which require precise tolerances and weight savings.

Within the consumer goods industry, aluminum permanent mold castings are frequently present in products including cookware, sporting equipment, and electronic housings. They also play a significant role in the manufacturing of industrial machinery parts, including pumps and valves, where reliability and performance are paramount. The versatility of aluminum permanent mold castings makes them an vital selection across multiple sectors, ensuring the production of top-quality, operational parts designed for specific applications.

Fundamental Design Factors for High-Precision Aluminum Castings

Developing precision aluminum castings calls for thorough consideration of numerous key factors to ensure maximum performance and functionality. One essential aspect is the selection of proper alloy compositions, which determine mechanical properties, corrosion resistance, and thermal conductivity. Designers must also account for the geometry of the components; complex shapes may demand specialized mold designs to prevent defects and ensure uniform cooling.

Furthermore, wall thickness must be optimized to equilibrate strength and weight, avoiding excessive material use while upholding structural integrity. Surface finish is an essential consideration, as it influences both aesthetic appeal and functionality. Correct draft angles should be incorporated to allow mold release without affecting the castings. Finally, tolerances need to be defined accurately, as precision in dimensions immediately influences assembly and operational efficiency. By considering these design considerations, manufacturers can generate high-quality aluminum castings perfect for a wide range of industrial applications.

Emerging Trends in Aluminum Permanent Mold Casting Technology

Notable innovations in aluminum permanent mold casting technology are emerging, propelled by the demand for improved efficiency and sustainability in manufacturing processes. Advancements in mold materials, such as the application of advanced ceramics and composites, are predicted to enhance durability and thermal performance. Automation and robotics will play a crucial role in streamlining production, decreasing labor costs, and boosting precision. Moreover, the integration of artificial intelligence and machine learning will refine the casting process, enabling real-time monitoring and adjustments to deliver superior quality control.

Environmentally responsible approaches, like the recycling of aluminum scrap and energy-efficient melting processes, will likely become standard. Furthermore, advancements in 3D printing will facilitate rapid prototyping of molds, allowing faster iterations and personalized designs. On the whole, these trends signal a transformative shift in aluminum permanent mold casting, aligning with the wider manufacturing industry's goals of productivity, sustainability, and innovative act now technology.

Popular Questions

What Sectors Benefit Most From Aluminum Permanent Mold Castings?

The automotive, aerospace, and machinery industries benefit greatly from aluminum permanent mold castings. These fields employ the lightweight nature, precision, and durability of castings to improve efficiency and performance in their respective applications and products.

Is It Possible for Aluminum Permanent Molds Be Used Again?

Yes, aluminum permanent molds can be reused numerous times. Their robust construction and ability to withstand wear enable multiple casting cycles, making them a cost-effective choice for manufacturing superior components across diverse manufacturing sectors.

How Does Temperature Affect Aluminum Casting Quality?

Temperature substantially affects aluminum casting quality; higher temperatures can increase fluidity, reducing defects, while excessively high temperatures may trigger oxidation and weaken structural integrity. Maintaining appropriate temperature ensures better dimensional accuracy and surface finish in castings.

What Extra Finishing Steps Are Needed Following Casting?

Once casting is complete, subsequent finishing procedures can include machining, surface treatment, cleaning, deburring, and polishing. These operations refine dimensional accuracy, improve surface finish, and ensure the final product satisfies specific performance and aesthetic requirements.

Are Aluminum Permanent Mold Castings Good for the Environment?

Aluminum castings produced through permanent mold processes are commonly viewed as eco-friendly due to their ability to be recycled and decreased energy consumption during manufacturing. Their longevity also results in minimized waste, supporting sustainable practices in industrial applications.